Main Business

Grab

———

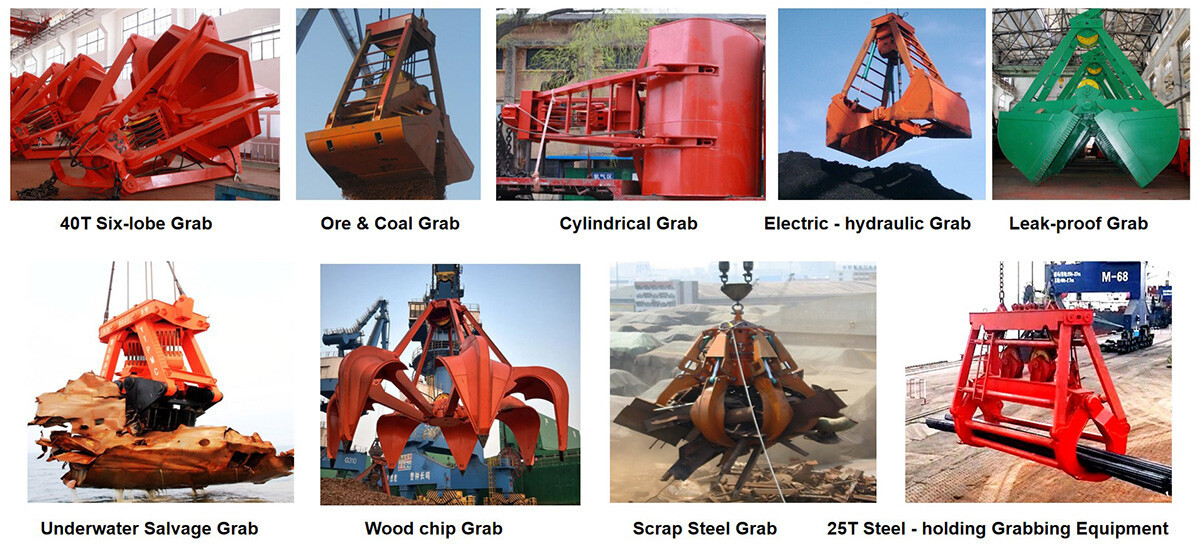

We can offer two - lobe grabs, multi - lobe grabs, ship unloader grabs, two - lobe leak - proof grabs, timber grabs, electrol - hydraulic grabs, hydraulically remotely controlled grabs, and underwater salvage grabs.

The grab product line has been developed to include various series and specifications, ranging from 5 tons to 500 tons, with four-cable, double-cable, and single-cable configurations; light, medium, heavy, and super-heavy types; as well as powered and non-powered options.

→Product Introduction

Grab Description

Two-shell leak-proof grab: Suitable for handling smaller cargoes, featuring reliable performance and a simple operating procedure.

Double-jaw grab: Suitable for port cranes, bridge-type unloaders, and grab cranes, etc., for handling bulk cargoes with a specific gravity of 0.6-3.2 tons per cubic meter and various particle sizes, typically grains, coal, cement, sulfur, mineral powder, and ore.

Multi-shell grab: Suitable for large portal cranes and grab cranes in ports, with high digging force, capable of handling larger granular cargo, typically used for scrap metal, ore, bauxite, barite, and other common materials.

Timber grab: Specialized for handling logs in port portal cranes and shipboard cranes during loading and unloading operations, generally available in single-cable, double-cable, and four-cable structures.

Ship unloader grab: The large-tonnage, multi-model grabs for ship unloaders are designed to meet the requirements of faster unloading speeds and higher grab capacity, and have been widely used in various coastal ports. High reliability, increased wear resistance, and a lighter self-weight are our constant pursuits.

Salvage grab: The world's first 500-ton and 800-ton underwater salvage grabs, which, relying on their own weight, can tear through the steel plates of sunken ships, thus enabling disassembly and salvage without the need for diving or blasting.

Our Flagship Product: Deep-Water Salvage Grab

1. Industry-leading 800T underwater lifting capacity

2. Domestically developed to address critical gaps in large-scale sunken vessel recovery

3. Enables safer, more efficient underwater dismantling and salvage operations

Key Features

Trusted by global ports and industrial operators, our grabs combine cutting-edge technology with unmatched reliability to streamline operations and maximize productivity.

Key Solutions

• Leak-Proof Bivalve Grab: Features a double-jaw design with stainless steel lining, ideal for dust-free handling of grains, cement, and sulfur.

• Wear-Resistant Multi-lobe Grab: Constructed with HARDOX® steel, designed for heavy-duty applications such as mineral ore, bulk cargo, and scrap recycling.

• Four-Rope Rotary Grab: Enables 360° rotation for precise positioning in port cranes and bridge-type unloaders, enhancing efficiency in bulk material transfer.

• High-Ton Hydraulic Grab: Delivers up to 800T capacity with electro-hydraulic control, perfect for ship unloaders and large-scale industrial operations.

• Wireless Remote Hydraulic Grab: Offers flexible, operator-safe control for tasks like timber handling and underwater salvage.

• Deep-water Salvage Grab: Max Capacity is up to 800T, domestically developed to address critical gaps in large-scale sunken vessel recovery.

FAQ

Q1: What information should I provide when I request a quote?

A: Thanks for your question. The more information you provide, the more accurate solution we can prepare for you! The information such as the lift capacity, span, lift

height, power source and other specials you give us will be more appreciated!

Q2: Is your products customized?

A: Yes, because of the different work environments, all our products are customized

depending on customer request! So if you give us more information about the lift

capacity, span, lift height, power source and other specials, we will give you a very

quick quote!

Q3. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q4: How do you make our business long-term and a good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit.

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Related suggestion

Online consultation

Request a Free Estimate