News

UHMWPE, "ultra-high molecular weight polyethylene. ", is a linear structure of polyethylene with an average molecular weight of over 2.5 million. This thermosetting polymer is formed by Ethylene, a butadiene monomer under the effect of a Barium-based catalyst. It is powder under the normal temperature while at higher temperature (300℃) it is in a solid state, and never flow.

With high molecular weight, it is excellent engineering thermoplastics with extraordinary performance and affordable price. Known as “amazing plastic”, it combines almost all straits of various plastics together with the advantages of wear resistance, corrosion resistance, impact resistance, self-lubrication, low friction loss, non-scaling, low-temperature resistance, health non-toxic, non-adhesive, non-absorbency which makes UHMWPE superior to other engineering plastics.

The higher its molecular weight is, the better it performs in wear resistance, and the harder it is to be shaped. UHMWPE was not put into use till the 1970s by some research institutes in Japan, the USA, and German. It was applied in the field of Bulletproof Composite Armor, aircraft, submarines, missiles, bulletproof vests, landing craft, spacecraft, satellites, helmets, machine parts, and mud pumps.

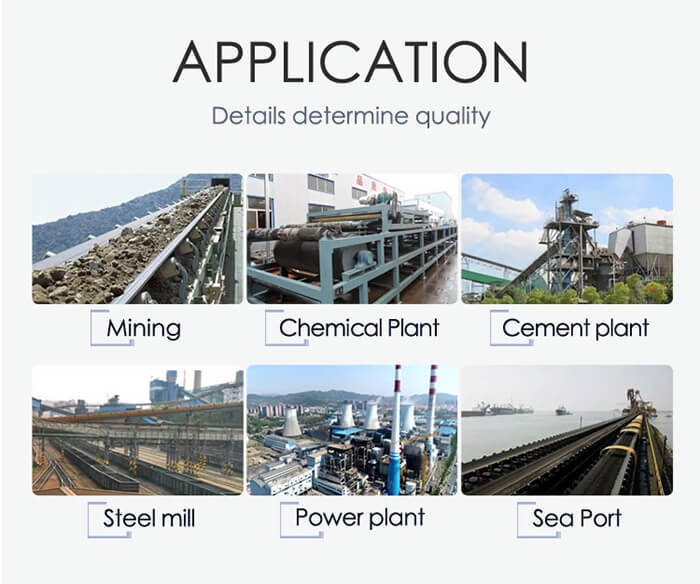

UHMWPE Idler application

Mines, Quarries, Cement Plants, Ports, Power Plants, Chemical Industries

Advantage of UHMWPE idler

Light in weight

Anti-corrosion

Impact resistant

Longer life

Self-lubrication Anti-static

Cost-effective

High wear resistant

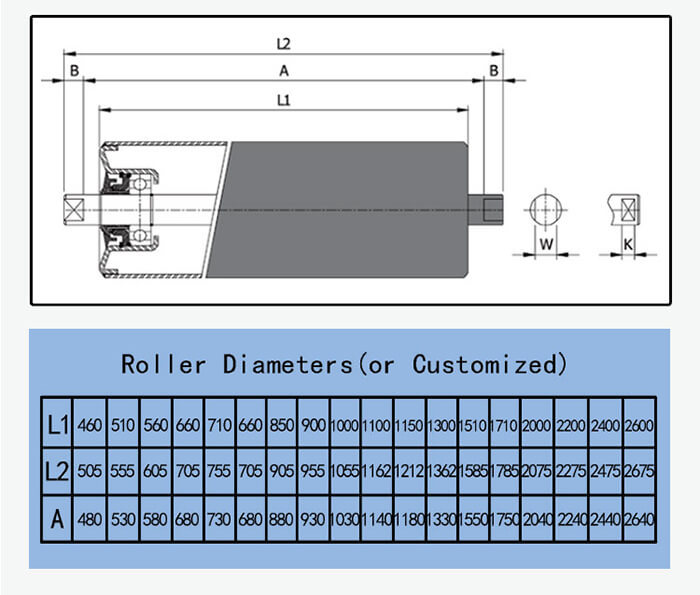

Structure of UHMWPE Idler

Roller pipe: UHMWPE material with a surface roughness of 0.00022mm

and molecular weight of over 4.5 million g/mol

Shaft: Q235 carbon steel

Bearing: 6305 2RS

Seals: Double labyrinth Seals made of Nylon 66 material

Rain cap: Made out of Nitrile Rubber

Greasing: Life sealed with Hi-Lithium Base Grease

Properties

Light Weight for Power Saving and Worker Safety.

Impact resistant: UHMWPE can absorb more impact because it is more resilient than steel

Anti-corrosion: UHMWPE Idler is much more resistant to salts, acids, and alkalis.Which provides longer life compared with steel rollers.

Anti-static: DRAGON UHMWPE for idler is anti-static to avoid sparkling.

Self-cleaning: UHMWPE is resilient, self-lubrication. Thus no cleaning and belt centering is required.

Increase Belt life: For its extremely smooth surface and low friction coefficient, the friction between

UHMWPE and rubber are much lower than steel and rubber, belt wear is reduced. Thus increased belt life.

It also has the fine self-lubrication and not easy card to die in bad conditions,

Low noise: (3-7DB)

Temperature range: -285°Cto 85°C

Request a Free Estimate