News

After a certain service period passes, mining companies have two options about pulley: buy a new mining pulley or opt for pulley refurbishment.

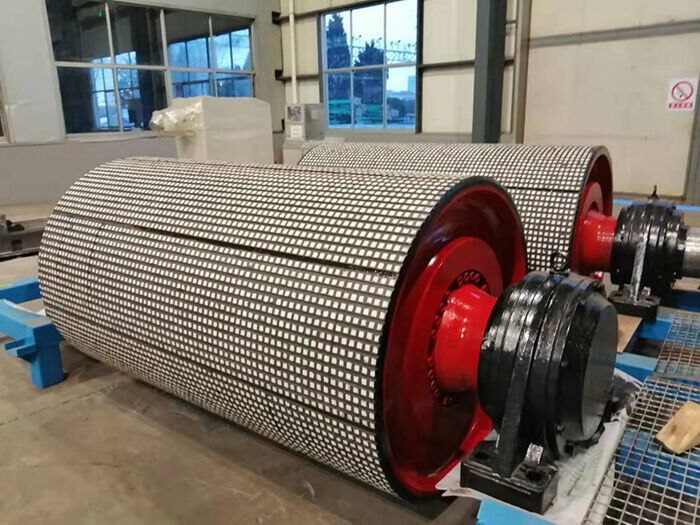

Mining conveyor pulleys are huge rotating components that run continuously for a long time. they suffer wear and tear and need constant monitoring and maintenance for an efficient operation.

What is pulley refurbishment?

Pulley refurbishment refers to the practice of reconditioning used pulleys for further use, giving a pulley a second life. Specific conveyor pulley components such as the shell and the shaft have considerably longer service lives compared to other elements.

Regular conveyor pulley maintenance is vital to ensure efficient operation and the long service life of the pulley. Pulley refurbishment prolongs the pulley’s service life and saves the cost of a pulley replacement.

Signs pulley needs refurbishment

During service, a mining pulley deals with various elements such as dust, abrasive product, moisture, heat, etc., causing its eventual wear and tear. This wear can manifest in multiple forms in the appearance and function of the pulley. Maintenance teams must be on the lookout for the following indicators to ascertain the need for a pulley refurbishment service.

Slack lagging

Slack lagging indicates that the bonding adhesive has worn out. Such lagging allows abrasives to get between the lagging and the pulley and allows abrasives and contaminants to get between the lagging and the shell causing wear and rusting.

Worn-out lagging

Damaged or worn-out lagging warrants a pulley refurbishment, as they leave the pulley shell exposed to abrasives. Missing lagging will also reduce the torque transfer required between the pulley and the belt.

Corroded locking elements

Corrosion of various pulley components may occur during service. Corroded locking elements are likely to have cracked bolts that could lead to imminent failure. A pulley refurbishment is recommended to prevent seizures, breakdown, and eventual downtime.

Unfamiliar noises

Sometimes, unusual noise may direct the maintenance team’s attention to the need for a pulley refurbishment. Worn-out bearings and lagging are usually the sources of such noises. It can also indicate a fractured shell or cracked welds that could lead to imminent damage to the conveyor. The pulley should be checked immediately and removed from service.

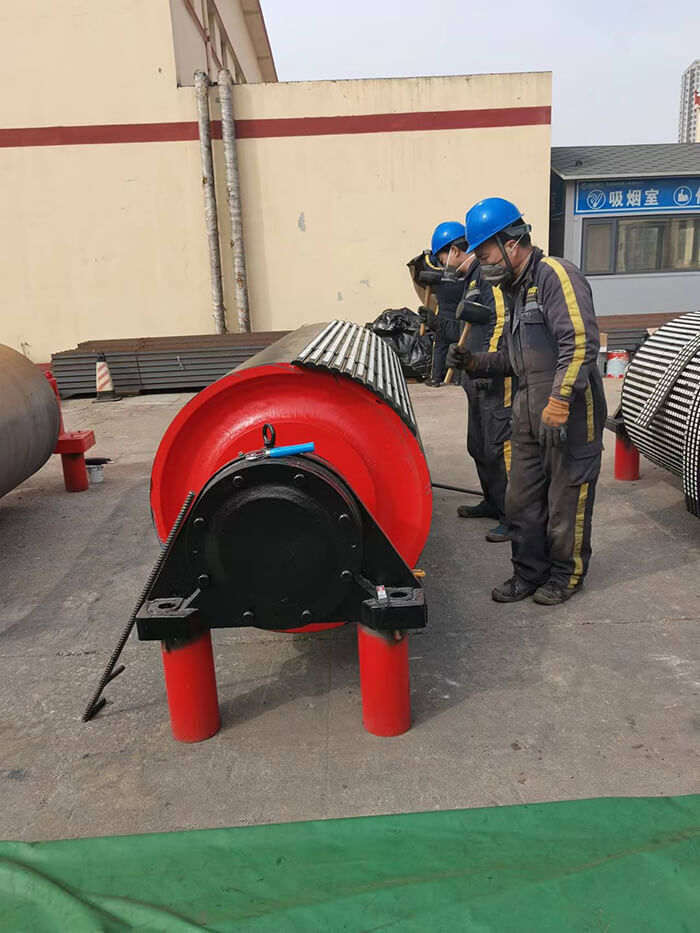

How is it done?

Pulley refurbishment involves the following stages.

1. Inspection and testing

After the pulley arrives at the workshop, a detailed inspection and testing are undertaken to determine the re-usability of major elements and if they meet new pulley standards.

2. Shell surface preparation for re-lagging

Resurfacing of the shell surface ensures that a smooth surface is available before the new lagging is attached.

3. Re-lagging and protective coating

The workshop then applies new lagging similar to the original or an upgraded version as requested by the client.

4. Renew all worn parts

Some workshops renew only the worn parts, while others may renew all worn parts. Wear parts such as the bearing and adaptor sleeves, locking elements, and housing seals may cause premature pulley failure if the workshop reuses older parts.

Benefits of pulley refurbishment

On observing any of the above issues, it is the maintenance team to opt either for a complete pulley replacement or refurbishment. Some distinct advantages that pulley refurbishment offers over pulley replacement include:

1. Cost savings

pulley refurbishment has significant cost savings. Pulley refurbishment is extremely cost-efficient if the shell and shaft are in good condition since they are the two most expensive conveyor pulley parts. Companies can save up to two-thirds of the cost of a new pulley by choosing pulley refurbishment.

The cost of running to failure could include structural damage, fire, and injury to personnel.

Worn lagging can lead to driving pulley slippage, replaced lagging eliminates that slippage which results in lower power draw needed and also reduces greenhouse emissions from less power demand.

2. Low lead times

Pulley refurbishment also saves time compared to sourcing a new pulley. There are fewer steps involved in inspecting and repairing an old pulley, which considerably brings down the lead time.

Pulley refurbishment is an excellent alternative to purchasing a new pulley, with the pulley repair cost being a fraction of the cost of a new pulley.

Request a Free Estimate