News

There are many bar gratings that are diverse in construction, material and purpose. With so many options available, determining the right fit for design and functional needs can sometimes be overwhelming.

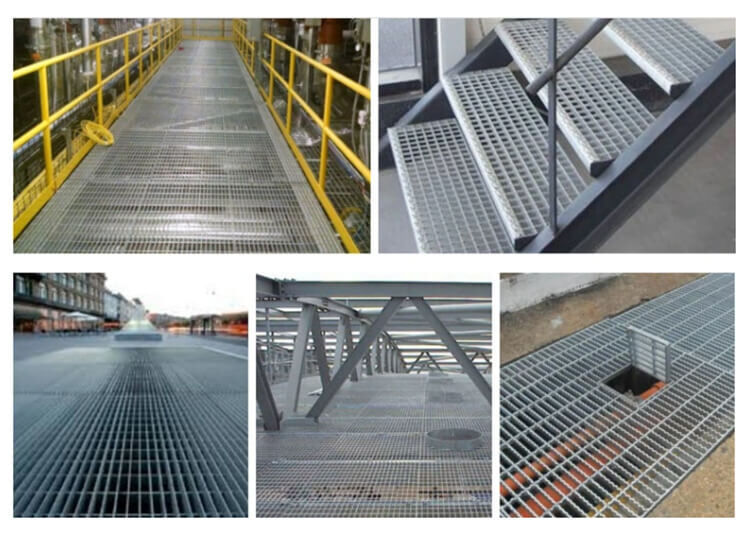

While always being used in new and creative ways, bar grating is most frequently seen in walkway applications. But how do you determine which type is best suited for your pathway? What are the benefits, usage and specifications of each?

Know the Application

Bar grating is an ideal option when high levels of strength and durability are required. Its high-performance, yet low-maintenance characteristics function well in rugged and severe environments. When determining the right bar grating item for your project, it is first helpful to envision exactly how the product will be used. Knowing the application will help guide you through the rest of the selection process.

For example, will it be carrying heavy vehicular loads, or will it be a walking surface for pedestrian traffic? In some cases, it may be a uniform load, where the full weight of a machine or object is resting on the entire span of the panel. Other times, the load being placed on the panels is a concentrated load, which simply means it covers a smaller area in relation to the grating and therefore changes the pounds per foot weight capacity when compared to uniform load. Always consult the correct load table before making your decision.

Grating Types

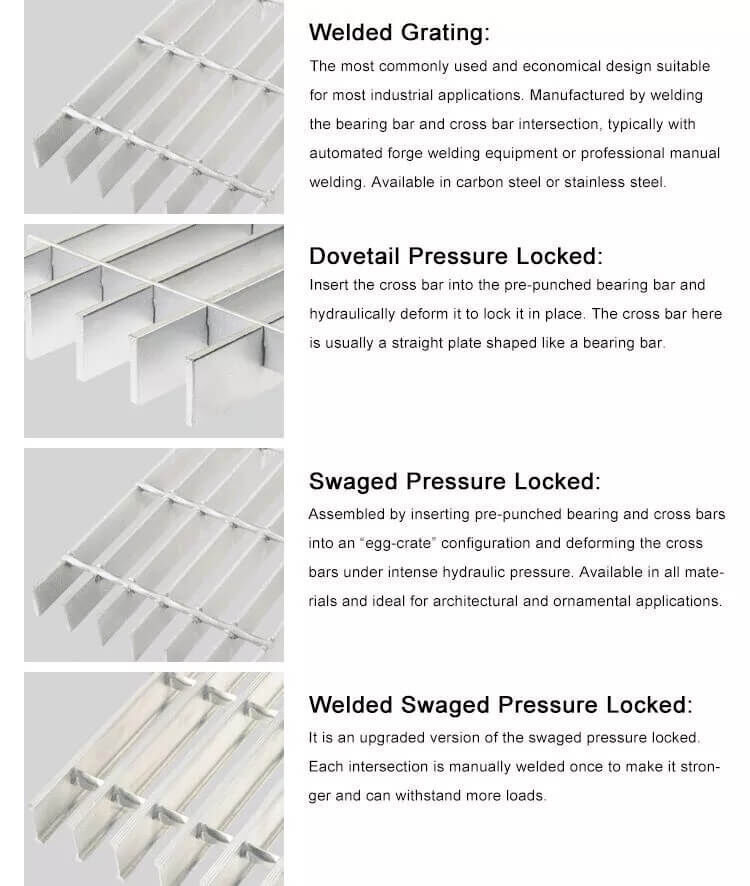

Once the intended application is known, the next thing to decide is the bar grating construction type: welded, heavy-duty welded, swage-locked or presslocked.

RPIC’s welded bar grating is durable and versatile, and is therefore one of the most popular bar grating choices. For even more strength and carrying capacity, heavy-duty welded is the most durable and secure construction, and is often used in areas with vehicular traffic. Swage-locked bar grating is made from aluminum, and thus has a high strength-to-weight ratio. Press-locked bar grating is optimized with a flush surface and bearing bars that are close together.

Strength, weight, environment and aesthetics are all factors that determine the primary material, whether it be lightweight aluminum, durable carbon steel, or corrosion-resistant galvanized steel and stainless steel. Also, decide whether you would like a smooth, serrated or grooved surface depending on your traction needs. Confirm that your chosen grating will be able to handle application loads. Load tables are available that make it easy to calculate and confirm load capacity. There are many charts, lists and details that can provide more comprehensive information about various bar gratings.

Request a Free Estimate