News

EPS panels, XPS panels, and PU panels are commonly used thermal insulation materials in buildings

1. XPS panel

XPS insulation panel is a hard foam material with a closed hole structure made of polystyrene resin with a few additives and extruded by heating. XPS panel has a perfect closed-hole honeycomb structure, which gives XPS panel very low water absorption, low thermal conductivity, high-pressure resistance, and aging resistance.

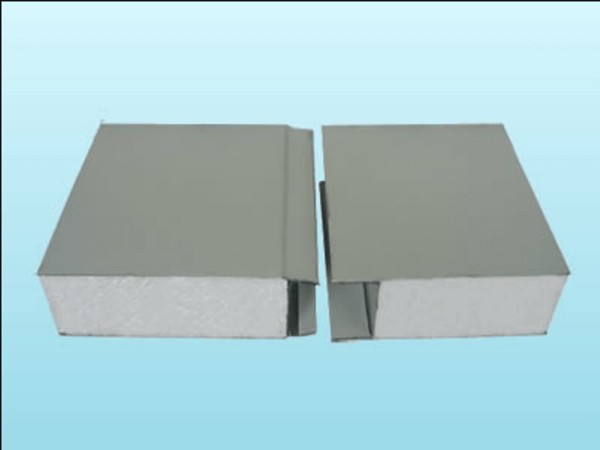

2. EPS Panel

EPS insulation panel is a foam material with a closed hole structure; it can be made into different densities, and different shapes of foam products, and can produce a variety of different thicknesses of foam plate. Widely used in construction, thermal insulation, packaging, refrigeration, industrial casting, and other fields. At present, it is mainly used in external wall insulation, external wall insulation, and floor heating. EPS board is a kind of thermoplastic material, containing 3-6 million independent closed bubbles per cubic meter volume, the volume of air is more than 98%, because the heat conductivity of air is very small, and is closed in foam plastic and can not convection, so EPS is a kind of heat insulation performance is very good material.

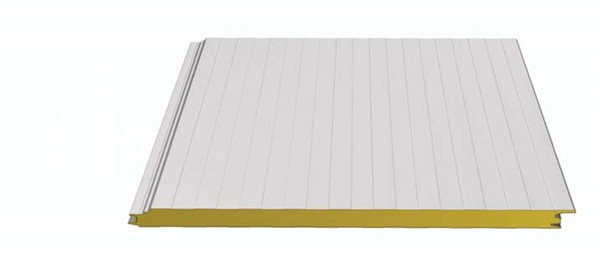

3. Polyurethane foam panel

Polyurethane hard foam board is a new type of synthetic material with insulation and waterproof function, its thermal conductivity is low, equivalent to half of the extruded board, and is the lowest thermal conductivity among all insulation materials. Hard polyurethane foam plastic is mainly used in building exterior wall insulation, roof waterproof insulation integration, cold storage insulation, pipe insulation materials, building boards, refrigerated vehicles cold storage insulation materials, etc.

4. Advantage of the polyurethane sandwich panel

(1) The adiabatic performance of the polyurethane board is better. On the premise of the same energy-saving index, the thickness of the insulation board can be reduced to improve the quality stability of the insulation system.

(2) Thermal stability The thermal stability of hard foam polyurethane can be up to 120℃, while the benzene plate is only 70℃. So above a certain temperature, easy to cause benzene plate secondary foaming, leading to plate crack cracking.

(3) Burning the base principle

Hard foam polyurethane is a thermosetting material, that is formed after heat combustion, which cuts off the further entry of heat and oxygen, hinders the further combustion of foam body, and is not easy to produce fire spread accident. Polystyrene foam is a thermoplastic material, heated to shrink and melt, and then dripping combustion.

Request a Free Estimate