Main Business

Slurry Pump

———

→Product Introduction

Slurry Pump Description

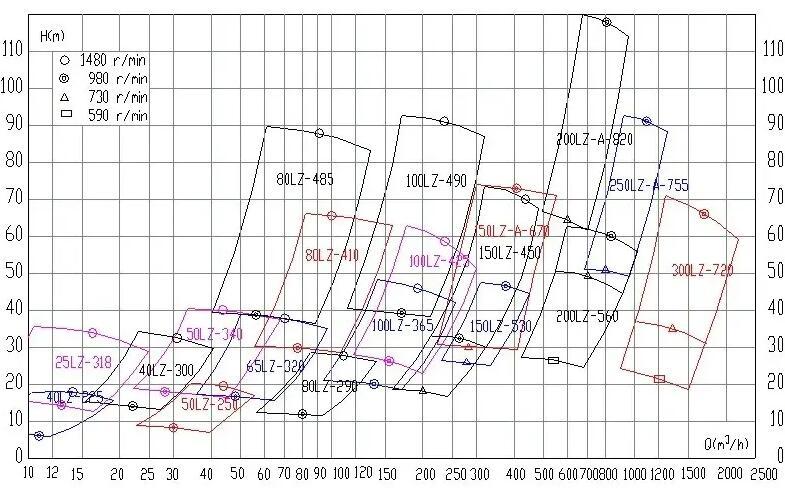

The LZ(Y) series slurry pumps are single-stage, single-suction, horizontal (vertical), double-shell (single-shell) centrifugal pumps, with a flow range of 7-2600m³/h and a head range of 7-125m. They can handle a maximum volume concentration of 30% and a maximum weight concentration of up to 60%.

The LZ(Y) series slurry pumps have over 50 specifications, meeting the requirements of different working conditions.

Product Parameters

Note:Except the above-mentioned model, we can also receive the special orders tailored to customers’ specific requirements.

Advantages

1.High Efficiency and Significant Energy-Saving

The LZ(Y) series of solid-liquid two-phase flow slurry pumps achieve high efficiency and notable energy-saving due to their thorough consideration of the flow of solid particles within the pump. The flow component profiles are designed to closely match the medium flow path, effectively guiding the flow with minimal energy loss. As a result, these pumps exhibit excellent energy conversion and high efficiency, with significant energy-saving effects. Actual measurements show that the series of pumps is, on average, 8-12 percentage points more efficient than traditional impurity pumps and 5 percentage points more efficient than domestic "Warman" pumps. Additionally, since the two-phase flow theory primarily focuses on slurry materials, the efficiency during slurry material transportation is higher than that during clear water transportation, with an average increase of 4-6 percentage points.

2. Good Abrasion Resistance and Long Service

Life of Flow Components under the guidance of two-phase flow theory, the flow component profiles are designed to closely match the medium flow path, significantly reducing the scouring and impact wear on the flow components during pumping. This reduces material wear. With the addition of advanced wear-resistant materials, the service life of the flow components is greatly extended, with an average increase of 3-6 times compared to traditional impurity pumps.

3. Good Cavitation Resistance and High-Level Arrangement

The pumps have good cavitation resistance, allowing for high-level arrangement.

4. Large Flow Cross-section Area and Capability to Handle Large Particles

The flow cross-section area is large, allowing the passage of larger particles.

5. Rational Structure and Easy Installation and Maintenance

The structure is practical and rational, and installation and maintenance are convenient.

Performance Chart

Applications

Our slurry pumps are widely applied across diverse industries. In aluminum plants, they handle abrasive slurries efficiently. In coal mining, they pump out coal - water slurries. Alkali plants benefit from their corrosion - resistance. Power plants use them for slurry tasks, and in river dredging, they move sediment - laden water.

Packaging&Shipping

FAQ

● Q: Are you a trading company or manufacturer?

We are a manufacturer, and we have been in centrifugal pumps manufacturing industry over 50 years.

● Q: What are your factory workshops?

Our factory produce includes casting, mechanical process, lathe process, heat treatment, assembly, test, etc. Warmly welcome to visit & test my factory any time.

● Q: How about your pump price?

Our pump price is factory - direct, offering you the best value. We focus on high quality for long - term cooperation. Our products are made with top - notch materials and advanced tech, ensuring durability. This quality - first approach keeps our costs down in the long run, making it a cost - effective choice for you.

● Q: How does your factory do regarding quality control?

Quality is a priority. we always attach great importance to quality control from the very beginning to the very end. Firstly, per quality management system procedures, we choose top - tier domestic suppliers to boost product quality. Authoritative test reports are available on request. Secondly, our factory has an in - house area and smart system for performance testing.

● Q: How to do if the pump or parts have operation problems within your warranty?

Please provide me with detailed information in a timely manner and send over the pictures or videos. We'll immediately and without delay formulate and send you the most suitable pump solution tailored to your needs.

● Q: We don't know which pump model we need, can you help us?

Yes, please tell me your detailed requirements, including the nature of the liquid, flow rate, head, etc. Our engineers' team will calculate and select the most suitable pump model for you, and offer a solution for you. Besides, we have our own R&D center, which enables us to provide customized solutions.

● Q: What are your advantages, and why should I choose you?

Quality: We could ensure greater reliability and less frequent replacements.

Delivery: We stock normal parts, enabling quick order fulfillment and short lead times.

Price: Enjoy cost - effective solutions, with the potential to cut costs.

Service: Our R&D, quality control, and marketing teams are ready to offer professional support whenever you need it.

Related suggestion

Online consultation

Request a Free Estimate