News

The advances in technology rule the era in which we live. From simple stone and wood buildings to enormous metal towers, architecture has changed considerably in the last century. Steel is considered a green product because it is entirely recyclable. For a brand-new home or business structure, the builder can purchase recycled steel. Some structures reach record heights, bridges cross the most significant rivers, and some sculptures bring together nations. Steel was essential to creating many of the world’s most recognisable buildings.

For aspiring civil engineers, steel structures are a crucial topic. Steel is an alloy of iron and carbon. Due to its hardness and tensile strength, it is utilised in construction and other applications. Steel is added to concrete because it has tensile strength; without it, concrete has a great deal of compression strength.

What is a steel structure?

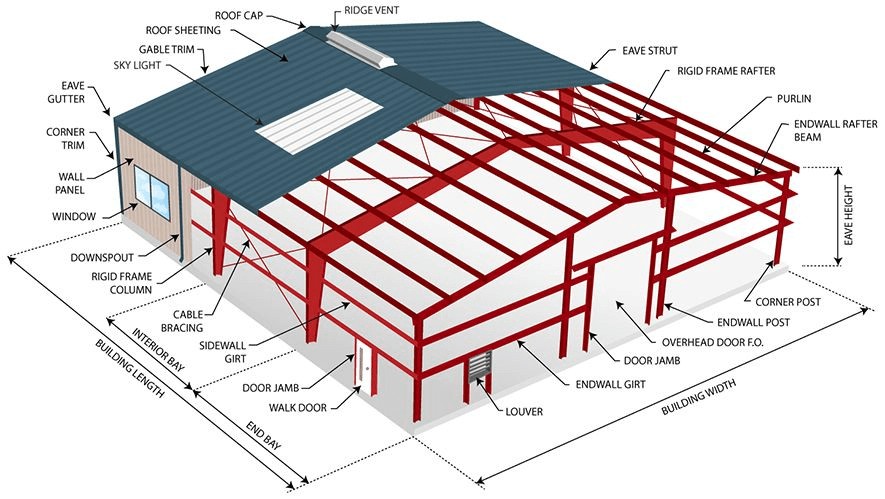

The term steel structure refers to a metal layout developed with structural steel pieces connected to support loads and provide comprehensive stiffness. This construction is reliable and employs fewer raw materials than different forms of structure like concrete and timber structures because of the high resilience degree of steel.

Steel is a material that is employed in almost every kind of structure in a contemporary building, including airport terminals, big industrial factories, high-rise constructions, equipment support systems, bridges, buildings, heavy industrial constructions, and pipe stands.

Steel fabricated with a proper form and chemical composition to satisfy the conditions of a project is understood as structural steel.

The steel compartments may be available in various shapes, heights, and meters, depending on the relevant project specifications. Some may be constructed by hot or cold rolling, while others may be built by joining flat or bent plates. Some common shapes are Plate, I-beam, Channels, and Angles.

Benefits of steel structure for residential construction

There are many benefits of using steel in residential construction. These include:

1. Strength and design freedom

In terms of colour, texture, and shape, steel gives architects a more creative look. Because it combines resilience, durability, beauty, accuracy, and malleability, it offers architects more flexibility to experiment with concepts and develop new solutions. Large open expanses without intermediate columns or load-bearing walls result from steel’s long-spanning capacity. It stands out for having the flexibility to bend to a certain radius, forming segmented curves or free-form combinations for facades, arches, or domes. Steel is less susceptible to on-site variability since it is factory-finished to the tightest requirements under well-regulated conditions.

2. Fast, efficient and resourceful

In any season, steel can be assembled fast and effectively. With little on-site labour, components are pre-manufactured off-site. Depending on the size of a project, an entire frame can be constructed in days instead of weeks, which results in a 20% to 40% shorter construction period than on-site construction.

For single homes in more challenging locations, steel frequently permits fewer contact points with the land, minimising the amount of excavation needed. A smaller, more straightforward foundation is possible due to structural steel’s lesser weight than alternative framing materials like concrete. These executional efficiency improvements translate to significant resource efficiencies and financial advantages, such as quicker project schedules, lower site management expenses, and an earlier return on investment.

Less than 150 °C causes little change in the steel’s characteristics. In hot workplaces, steel structures are therefore appropriate, but heat insulation panels should be used to

3. Adaptable and accessible

A building’s function can alter drastically and quickly today. A tenant can request modifications that considerably raise the floor load. Depending on the needs and space consumption, walls may need to be moved to create new interior layouts. Steel construction allows for such adjustments.

Non-composite steel beams can be combined with the floor slab already in place, cover plates can be added to the beams to boost strength, and beams and girders can easily be reinforced, supplemented with more framework, or even moved to handle different loads. Existing communication, computer networking, and electrical wiring may all be easily accessed and modified because of steel framing and floor systems.

4. Endlessly recyclable

When a steel-framed building is taken down, its parts can either be recycled or sent back into the closed-loop recycling system utilised by the steel industry. Steel may be recycled indefinitely without losing any of its qualities. Nothing goes to waste. Because about 30% of today’s new steel is made from recycled steel, steel reduces the need for natural raw resource use.

5. Added fire resistance

The industry now has a solid grasp of how steel buildings react to fire because of extensive testing of structural steelwork and whole steel structures. Modern design and analytical methods enable exact specification of fire protection needs for steel-framed structures, frequently leading to significant reductions in the amount of fire protection needed.

6. Earthquake resistance

In terms of size, frequency, length of time, and location, earthquakes are unexpected. Because it is malleable and flexible by nature, steel is the material of choice for design. Under heavy pressures, it flexes as opposed to breaking or disintegrating. The primary purpose of many beam-to-column connections in steel buildings is to support gravity loads. They can, however, also withstand substantial lateral loads caused by wind and earthquakes.

It can withstand severe winds, earthquakes, hurricanes, and heavy snowfall, among other extreme forces and adverse weather conditions. Termites, bugs, mildew, mould, and fungi do not affect them; unlike wood frames, they are also resistant to corrosion.

7. Lighter and less environmental impact

The environmental impact of the construction is lessened by the fact that steel constructions can often be substantially lighter than concrete counterparts and need less extensive foundations. The utilisation of transportation and fuel is decreased because they use fewer and lighter materials. If necessary, steel piling foundations can be removed, recycled, or reused at the end of a building’s life, leaving no trash behind.

Steel is energy-efficient because heat quickly escapes from steel roofing, keeping homes cool in hotter climates. For better heat retention in cold areas, double steel panel walls can be adequately insulated.

Request a Free Estimate