Main Business

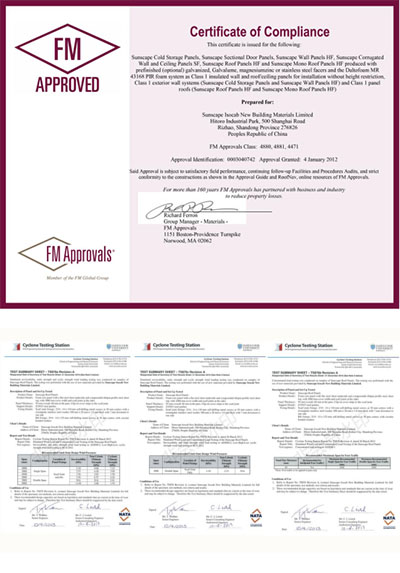

FM Approved Sandwich Panel

———

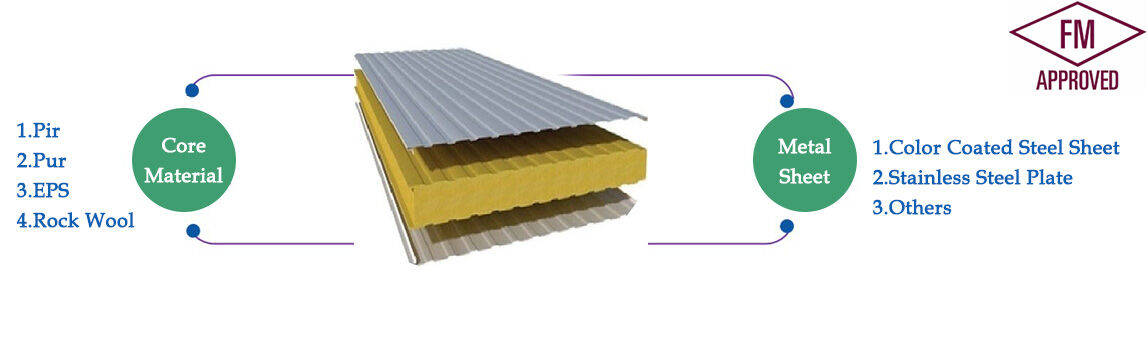

Sandwich panels are commonly used building material used in industrial facilities, commercial buildings, cold storages, residential buildings as well as buildings for agricultural and husbandry. Depending on different core materials, RPIC offer PU/PIR sandwich panel, Rockwool and Glasswool sandwich panel and EPS sandwich panel for your choice.

→Product Introduction

Sandwich Panels

According to different core material, we offer Pur / Pir sandwich panel, Rockwool and Glasswool sandwich panel and EPS sandwich panel for your choice.

● Efficient Contruction: Sandwich panel provide easy installation which can be triple faster than usual concrete building. It can also has less affection from weather during construction. It allows large span, the supporting structure can be lighter.

● Perfect Energy Saving : Sandwich panels provides high thermal insulation by means of PUR, PIR, EPS and Mineral Wool insulation materials. It has lower U value and higher insulation capability .

● Environmental Friendly: Sandwich panels require less maintenance than concrete an brick structure; repainting is not required. It is more economical and environmental friendly.

● Safe, Durable and Reusable: Sandwich panels are light weight that are easy and safe to handle during con- struction. Also can be easy assembly and disassembly.

● Versatility: Sandwich panel can be used for various applications, such as pre-fabricated steel buildings , warehouse, walk-in cold storgaes, cleanroom, farm, food processing plant and etc.

● Benefit and Value: Compare with traditional construction, sandwich panel are more economical in terms of labours,machines,time, maintenance.cost etc. It enables big saving in future operation costs.

Propertis Of Sandwich Panels

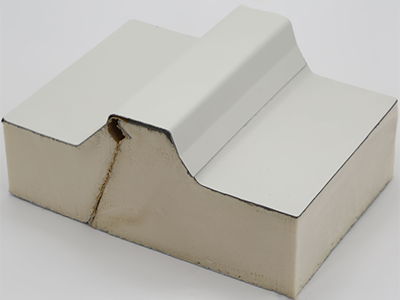

1:Pur / Pir Cold Room Panel

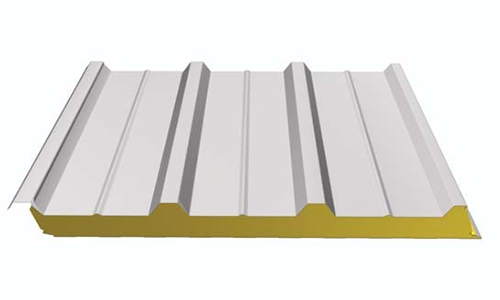

2: Pur / Pir Roof Panel

3: Pur / Pir Wall Panel

Other Major Products

● Rock Wool Sandwich Panel

Type: wall / roof / cold room panel

Core Thickness: 50-200mm

Steel thickness: 0.4-0.8mm

Length : Can be customized

● EPS Sandwich Panel

Type: wall /roof panel

Core Thickness : 50-200mm

Steel thickness: 0.4-0.7mm

Length: Can be customized

● Foam Ceramic Sandwich Panel

Type: partition wall /

decorative/ external wall

Thickness: 70-150mm

Length: 2400-3200mm

Achievements for Reference

● Food Processing Plant

● Cold Room Project

● Industrial Building

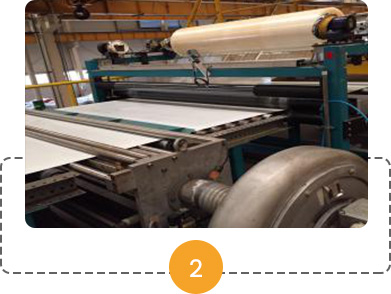

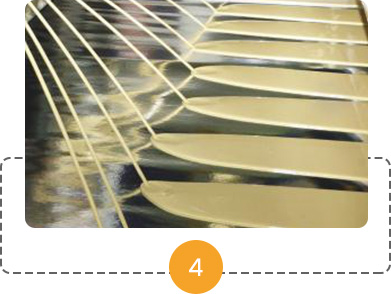

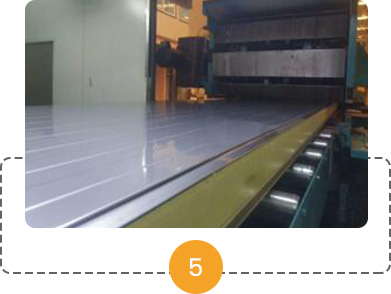

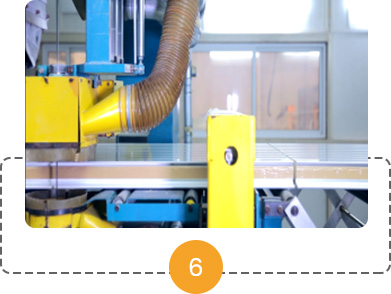

Sandwich Panel Production Process

Uncoiling

Film Laminating

Sheet Profiling

Chemical Foaming

Molding

Cutting

Curing

Packing & Stacking

Strict Quality Control

● Sandwich Panel Testing Equipment

With the exception of introducing the full set of Germany production line, relevant sandwich panel testing equipment are timely purchased in. Following parameter can be tested in the laboratory.

> mechanical performance of sandwich panels

> close-cell rate of foams

> fire resistance of foams

> heat transfer coefficient of foams

> stability of product dimensions all production are in strict accordance with current quality control standard in Europe.

● High Quality Material

> steel sheets are produced by color-coated line(introduced from Nippon Steel), performances of which are all conforming with European standard.

> Foam mateirals are supplied by the world top four PUR suppliers such as Bayer, DOW, Huntsman and BASF.Sunscape has also established long-term cooperative mechanism with them to make efforts for the development of PUR sandwich panels.

Packing & Delivery & Payment

Flatracks

Nude

Truckage

About Us

Shandong Sealand Equipment Group Rizhao Co.,Ltd. (RPIC), is a large comprehensive state-owned enterprise combining industrial products research and manufacture, steel structure and equipment producing, general contracting service for industrial system and ships & equipment building and maintenance. The main business scope covers port, marine equipment, mining, electric power, cement, paper making and other industries. With excellent management team, outstanding professional technology, splendid culture background,abundant industrial experience, Rizhao Port Shipbuilding & Machinery Industry Co., Ltd is dedicated to cultivating itself an integrated general contractor combining design and development of industrial products, processing and manufacturing of steel structure and new building materials, operation and maintenance of port process system engineering and equipment, and strives to provide customers with more premium comprehensive services adhering the concept of "Based on port, technology innovation, products leading and integrated services ".

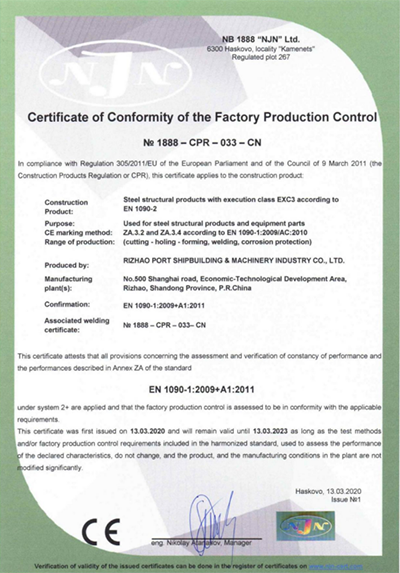

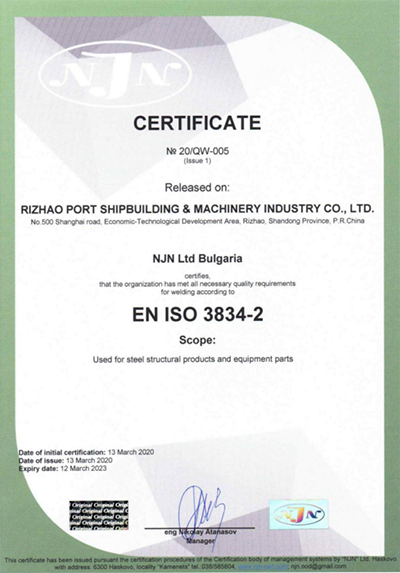

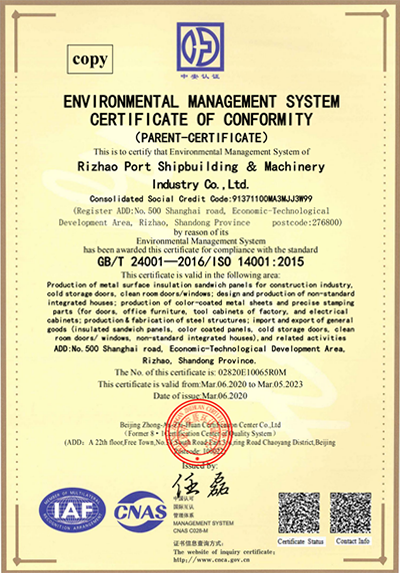

Company Certificate

FAQ

● Are you a manufacturer or a trading company?

We are a well-known sandwich panel manufacturer in China, and we also export them.

● What are the advantages of the FM sandwich panel?

The chemical raw material formula of insulation core layer has passed the test of FM company, its fire prevention and insulation index exceeds the general panel requirement, such as accidental fire, can guarantee the insurance compensation of FM company.

● What is the R value of polyurethane sandwich panel ?

The R value of polyurethane sandwich panel depends on the thickness of the panel and the thermal conductivity of the core layer (K value). For example, our 80 mm thick polyurethane board has a R value of 3.6. R=T/K.

● What certifications do you have for your panel ?

Our polyurethane products have obtained U.S. FM certification, Australian wind pressure test certification, European standard EN-13501-1 fire grade certification, as well as ISO9001 international quality system certification and ISO14001 international environmental management certification.

● What are the current export markets?

So far, our products are exported to Vietnam, Thailand, Singapore, Malaysia, Bangladesh, Japan, Australia, Korea, Canada, Mozambique, Indonesia and more than ten countries. In Vietnam, successfully compete with Kingspan andwin CP Group project.

● Is it possible to suggest suitable panel specifications?

For cold storage, we need to know the location of the project, indoor temperature and temperature difference between inside and outside. We have a professional technical team to provide you with a full range of early services, including design and consultation.

Related suggestion

Online consultation

Request a Free Estimate