Main Business

→Product Introduction

Rock Wool Sandwich Panel

Rock wool is an artificial inorganic fiber made of high-quality natural rocks such as

basalt and gabbro as the main raw material, and is made by

high-temperature melting and fiberization

Rock wool is an artificial inorganic fiber made of high-quality natural rocks such as basalt and gabbro as the main raw material, and is made by high-temperature melting and fiberization. Rock wool sandwich panel consist of two layers of high quality metal sheet (color coated steel plate, galvanized steel plate ) with a high density centre core rock wool. They are highly preferred for their thermal conductivity, low combustibility and high mechanic resistance. Rockwool Sandwich panel has wide applications as roofs, walls, ceilings and are used in the construction of commercial and industrial buildings, Cold rooms and Clean rooms, Refrigerated buildings, Warehouses, Cold storages, Office buildings, Prefabricated containers and cabins, Food processing units, Malls, etc.

Product detailed Image

● Cold room panel

Pure Rock wool Cold Room Panel

Pure Rock wool Cold Room Panel

Pu Sealing Rock wool Cold Room Panel

● Roof Panel

Pu Sealing Rock wool Roof Panel

Pu Sealing Rock wool Roof Panel

Pu Sealing Rock wool Roof Panel

● Wall Panel

Pu Sealing Rock wool Wall Panel

Pu Sealing Rock Wool Wall Panel

Pu Sealing Rock Wool Wall Panel

Key Advantages

● Fire Resistance: grade A1,Non-combustible, which has improved the overall fireproof performance of steel buildings.

● Fast Construction: it is fast and flexible to install on the construction site. The construction period can be shortened by more than 40%.

● Excellent performance in thermal insulation and sound absorption: Through testing, the sound insulation effect of a sandwich panel with a density of 120kg/ m³ rockwool as the core material can reach RW=29-30dB

● Both sides of the tongue and groove are filled with polyurethane foam, which can effectively prevent heat conduction and rain leakage and improve the overall strength

● High acidity coefficient, reducing corrosion to metals

High density rock wool core material

● Rock Wool: 90-150kg/m³

● Glass Wool: 50-80kg/m³ metals

High quality metal sheet

● Prepainted galvanized steel

● Stainless steel

● Bao Steel, SD Steel, Guanzhou Steel

Rock wool panel production line

● Annual capacity: 2000.000m²

● Double-crawler length: 24m

● Production speed: 6m-8m per minute

● Thickness: 50mm-200mm

Techical Parameters

Successfull Cases

Factory workshop

Warehouse

Integrated housing

Poultry House

Industrial factory building

Cold Storage

Prefabricated containers

Pharmaceutical Logistics

Main Equipment & facility

Salvagnini Production Line

MKM Drilling And Milling Machining Line

Longitudinal Shear Production Line

Flying Shear Production Line

Rock Wool Sandwich Panel Production Line

Packing & Delivery & Payment

Flatracks

Nude

Truckage

About Us

Shandong Sealand Equipment Group Rizhao Co.,Ltd. (RPIC), is a large comprehensive state-owned enterprise combining industrial products research and manufacture, steel structure and equipment producing, general contracting service for industrial system and ships & equipment building and maintenance. The main business scope covers port, marine equipment, mining, electric power, cement, paper making and other industries. With excellent management team, outstanding professional technology, splendid culture background,abundant industrial experience, Rizhao Port Shipbuilding & Machinery Industry Co., Ltd is dedicated to cultivating itself an integrated general contractor combining design and development of industrial products, processing and manufacturing of steel structure and new building materials, operation and maintenance of port process system engineering and equipment, and strives to provide customers with more premium comprehensive services adhering the concept of "Based on port, technology innovation, products leading and integrated services ".

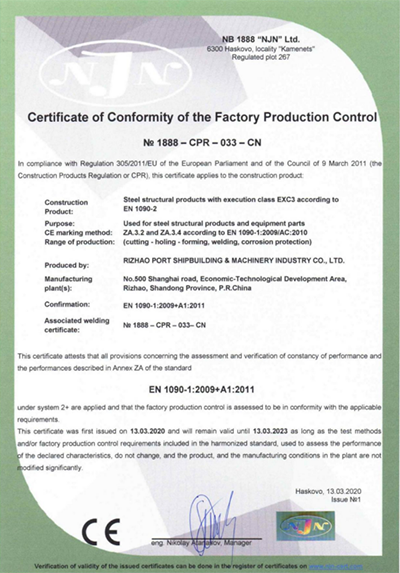

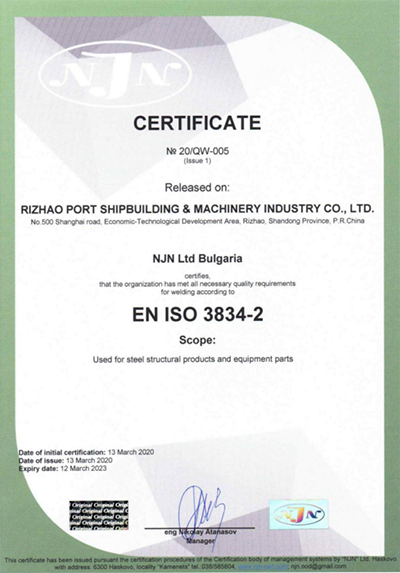

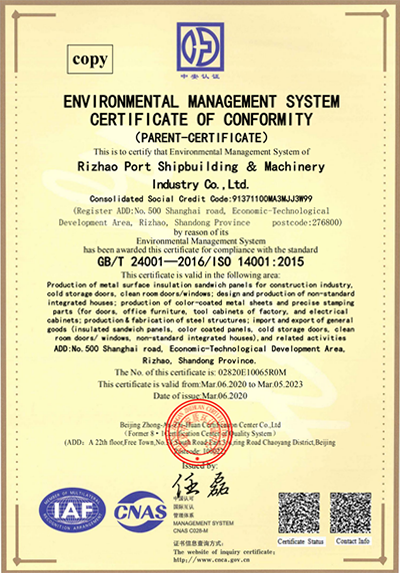

Company Certificate

FAQ

● Are you a manufacturer or a trading company?

We are a well-known sandwich panel manufacturer in China, and we also export them.

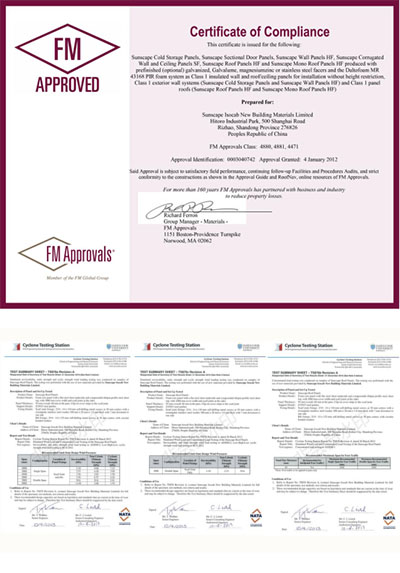

● What are the advantages of the FM sandwich panel?

The chemical raw material formula of insulation core layer has passed the test of FM company, its fire prevention and insulation index exceeds the general panel requirement, such as accidental fire, can guarantee the insurance compensation of FM company.

● What is the R value of polyurethane sandwich panel ?

The R value of polyurethane sandwich panel depends on the thickness of the panel and the thermal conductivity of the core layer (K value). For example, our 80 mm thick polyurethane board has a R value of 3.6. R=T/K.

● What certifications do you have for your panel ?

Our polyurethane products have obtained U.S. FM certification, Australian wind pressure test certification, European standard EN-13501-1 fire grade certification, as well as ISO9001 international quality system certification and ISO14001 international environmental management certification.

● What are the current export markets?

So far, our products are exported to Vietnam, Thailand, Singapore, Malaysia, Bangladesh, Japan, Australia, Korea, Canada, Mozambique, Indonesia and more than ten countries. In Vietnam, successfully compete with Kingspan andwin CP Group project.

● Is it possible to suggest suitable panel specifications?

For cold storage, we need to know the location of the project, indoor temperature and temperature difference between inside and outside. We have a professional technical team to provide you with a full range of early services, including design and consultation.

Related suggestion

Online consultation

Request a Free Estimate